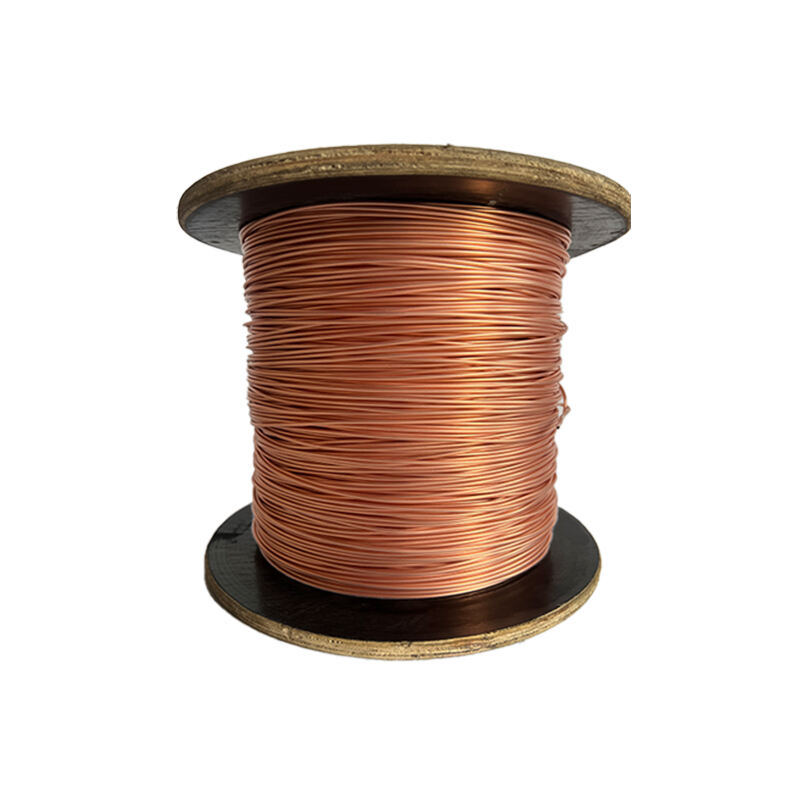

Copper Wire is a valuable resource that has many applications so it is easily recycled including Motor Winding. If you need to select the proper copper wire for your winding – that is the wire for your motor, generator, or transformer – just follow the procedure below. Use high quality copper wire to make the product work with high efficiency.

A few things to keep in mind when you are determining which copper wire is best for motor winding: Keep in mind the gauge or thickness of the wire. Heavier wires are fitted for larger motors and, conversely, smaller wires for smaller motors. You also want to think about the insulation of the wire and how it will affect the efficiency of the motor.

There are many advantages of copper wire as motor winding. High quality copper wire ensure its stability, making the motor more durable and less prone to damage. Moreover, good copper wire conducts electricity more efficiently that can help the motor to work more stable.

Motor efficiency With the high levels of copper wire required also at eye: diameter or above in a motor, the unit efficiency can be just as high as well. The copper wire is used to make the coils which produce the electromagnetic fields required for the motor to work. The motor has better performance and longer using life with high-quality copper wire. What this means is that the motor can output more power while using less electricity, which can be used to save energy and cut costs.

Thermal properties Insulation of copper winding wire in motor is very important to make sure the motor can run well. Insulation acts as a protective barrier for the wire, and also prevents electrical currents from seeping out. Maintaining the T the wire on the copper when T it should be insulated, what are the choices of materials and wrapping methods.Motor insulation should be chosen based on the characteristics of the motor.

There are a number of ways to achieve optimal motor performance with copper wire winding. One method is to use a thicker wire - it will possibly raise the power in the motor. Another tactic is to use a number of layers of copper wire during winding which can increase the motor"s efficacy. Through these methods, you can increase the motor’s performance and have it run smoothly and most efficiently.

Copyright © Zhengzhou Shengweite Industrial Co.,Ltd. All Rights Reserved - Privacy Policy - Blog