Copper pipe heating coils are components used in many machines and systems that require heat. Those coils are constructed using copper pipes bent into forms that aid in the even spreading of heat. Copper is used because it rapidly conducts heat and doesn’t quickly rust. When they do, heating coils make systems more efficient and longer-lived. Our copper pipe heating coil at Shengweite is strong, flexible and meticulous. For the largest of factories to a small garage workshop, our coils keep them all working and warm. We often get asked what makes a great heating coil and how to use it without hiccups. Let’s discuss what to look for in the best ones to buy, as well as preventing problems when installing them.

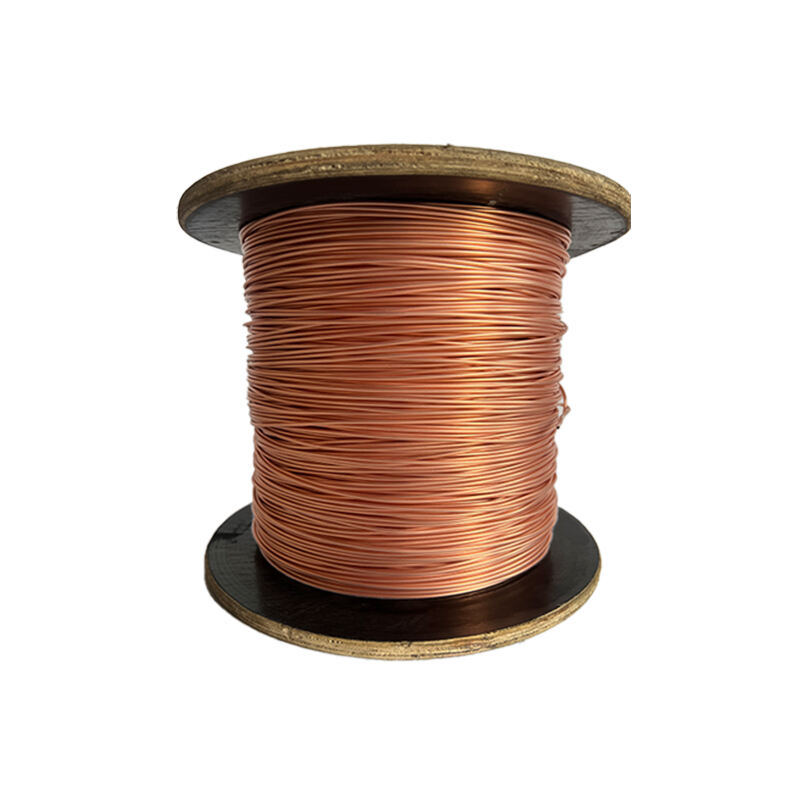

Selecting the correct copper pipe heating coil isn’t a matter of just purchasing any copper pipe you find. Quality is key, because those coils have to be able to resist heat and pressure without cracking or leaking. The first thing is the copper pipe thickness. Skinny pipes could save you money, but they might wear out quickly or burst under pressure. The copper Shengweite uses for its coils is thick enough to hold up over time but still easy to bend into the formations you want. A second factor is how the coil is constructed. Weak spots: Some coils have joints or welds. The way we manufacture grab sample coils allows for smooth bends and strong joints helping you to keep the coil leak free. If you’re shopping wholesale, ask that the supplier tests every coil for leaks and heat resistance. This testing step implies that you get coils that work well right from the beginning. Also, keep in mind the size and shape of the coil. Some uses call for tight loops, others big coils. Shengweite has many sizes for all kinds of machines or heating system. Don’t forget to inquire about the copper grade as well. Pure copper has better heating properties and will last longer than copper mixed with too many other metals. Occasionally cheap coils are made from low-quality copper, which corrodes or shakes off heat more quickly. Keeping an eye on these details lets you get the most value. A common mistake many buyers make is to decide based on price alone; but inexpensive coils can be problematic in the long run, leading to leaks or insufficient heating. Tot in lap, of course) Is better to pay a little extra for coils that are made with care. We have had customers that save money up front but replace coils way too soon. That’s also the reason why Shengweite prioritize quality from beginning to end. When you buy from us, you receive coils that accommodate your particular application and don’t have issues pop up out of nowhere. For coils that are made to last, and to perform well, ask us about our products and what we do that sets them apart. In fact, we also offer specialized products like Enamel copper flat wire Q (ZYXY) (EIAIWB200) that complement our heating coil solutions for enhanced performance.

It may look easy to install copper pipe heating coils, but you will likely have issues if it’s not done properly. There’s no shortage of rookie mistakes that can make you bend the coil too hard. Copper pipes are prone to breaking if bent too much or twisted improperly. Installers sometimes try to cram coils into tight spaces, and fail to be gentle. The coils of Shengweite are meant to be pliable, and yet that takes some handling.tip for ed. Another is failure to clean the pipes before installation. The coil may become fouled with dirt or oil, preventing transfer of heat (and promoting corrosion) in the future. Again, we recommend cleaning the coil surface thoroughly before installing into any system. Also, connections matter. Perfectly fine if the ends of your coil are welded to other pipes or fittings, but leaks occur rapidly if not. With the proper tools and an eye on every joint, leaks don’t have to be a fact of life. On occasion, people fail to pressure-test after installation. It's crucial to be able to identify leaks before running the system at full capacity. At Shengweite system, we suggest testing every coil installation with air or water pressure in order to find faults early. Another problem can be not leaving space for expansion. Copper expands when it is heated and if the coil is pinched too closely, it can split or spread open. Making room for movement is one small step that can prevent big ones later on. Installers occasionally fail to do that, and have to repeat the work. Temperature control is also important. If the coil heats up too much or isn’t evenly heated, it could wear out quickly, or worse, damage the entire system. Then confirm that the heating system is appropriately matched to those limits of the coil.” It’s all about keeping things safe and running longer. We've seen this neglected and then coils fail within a few months. Just taking a little time during installation to do these things really makes a difference. Shengweite hopes to assist you from avoiding such problems, and we do with clear guides. As long as you do the job carefully and honor the coil’s requirements, your heating system will perform well without issues for many years. For added protection, consider using our Waterproof line to safeguard the coils from moisture and damage during installation.

Copper pipe heating coils: Ready-to-be-used elements for HVAC systems Copper pipe coil heaters are very practical spare parts in the field of heating, ventilation and air conditioning. These coils transfer heat from one location to another to keep rooms warm and comfortable. One major advantage of running copper pipes through these heating coils is that copper makes an excellent heat conductor. That makes it easy for heat to move quickly through copper pipes, and as a result, the HVAC system operates more effectively (and uses less energy). As a heating coil composed of the copper pipes is heated, air or water can be warmed more quickly than if other metals were present. This saves money on energy bills because the system doesn’t need to work as hard, or for as long, to heat a room.

Copper pipe heating coils are also good because of the strength and longevity that comes with copper. It doesn’t snap or wrinkle easily, which is crucial for a very simple reason: a heating coil has to keep heating even when this thing’s been running all day. Copper also does not rust or tarnish as quickly as other metals. This type of maintenance prevents the heating coil from getting dirty and maintains its efficiency so the air is kept fresh and clean. Copper lines don’t need as many repairs and are less likely to leak and flood the place; if they did, it could damage a home or knock out its heating system.

Copper pipe heating coils are also easy to bend and orient in various HVAC configurations. Shengweite manufactures copper coils that can be shaped in many ways so they can fit neatly inside heating machines or air conditioners. This helps engineers design systems that make the most of space and function more smoothly. Lastly, copper is environmentally friendly because it is recyclable multiple times without losing its excellent characteristics. When you select Shengweite copper pipe heating coils, you are receiving a product that keeps your home warm and helps save money while protecting the Earth. To further enhance coil durability and insulation, we also supply related products like Flat wire with paper wrapped.

Another factor is keeping the copper pipes from being damaged. Occasionally copper can become scratched or damaged during shipping, handling and installation. Shengweite ensures that their coils are packed safely and offers suggestions on how to handle them cautiously. When you are installing the heating coil in an HVAC system, it should be put where it can not experience impact or pressure from other parts. Plus, a regular cleaning can help to keep the coil functioning properly. Dust or dirt on the pipes can clog up the paths of heat. Shengweite gives advice on cleaning to the consumer, so that the coil keep like new.

Copyright © Zhengzhou Shengweite Industrial Co.,Ltd. All Rights Reserved - Privacy Policy - Blog