Copper coil electric motors are need to provide the power to run all day to day devices. From kitchen appliances to children's toys and more, these motors operate inevitably in the background, coming to life to keep everything running as it should be In this quick guide, we are going to take a closer look at the mechanics of a copper coil electric motor and discuss why copper coil engines are the best choice for if you want a motor that is swift, responsive and efficient.

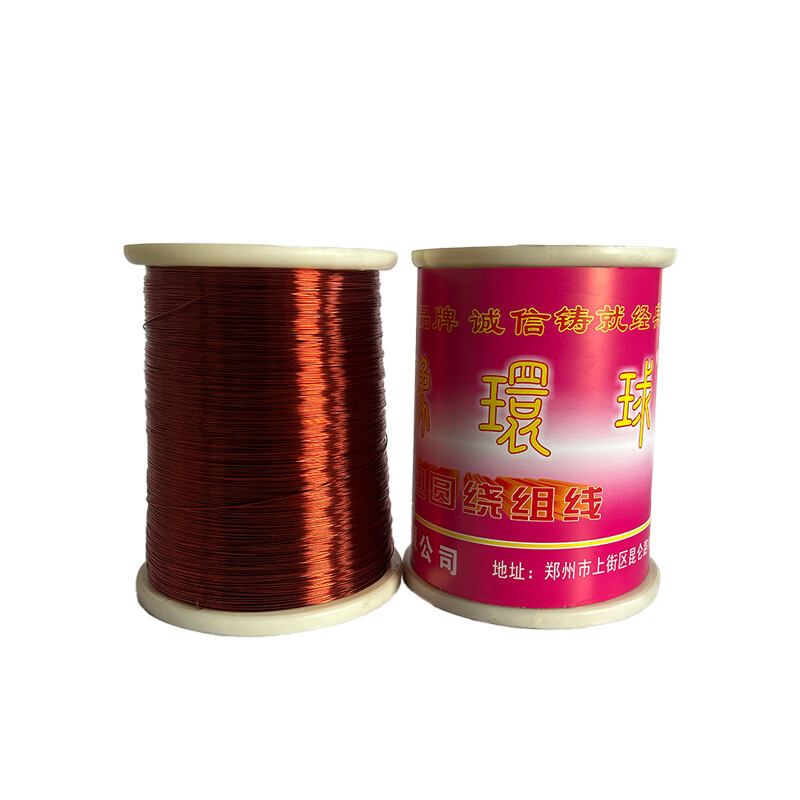

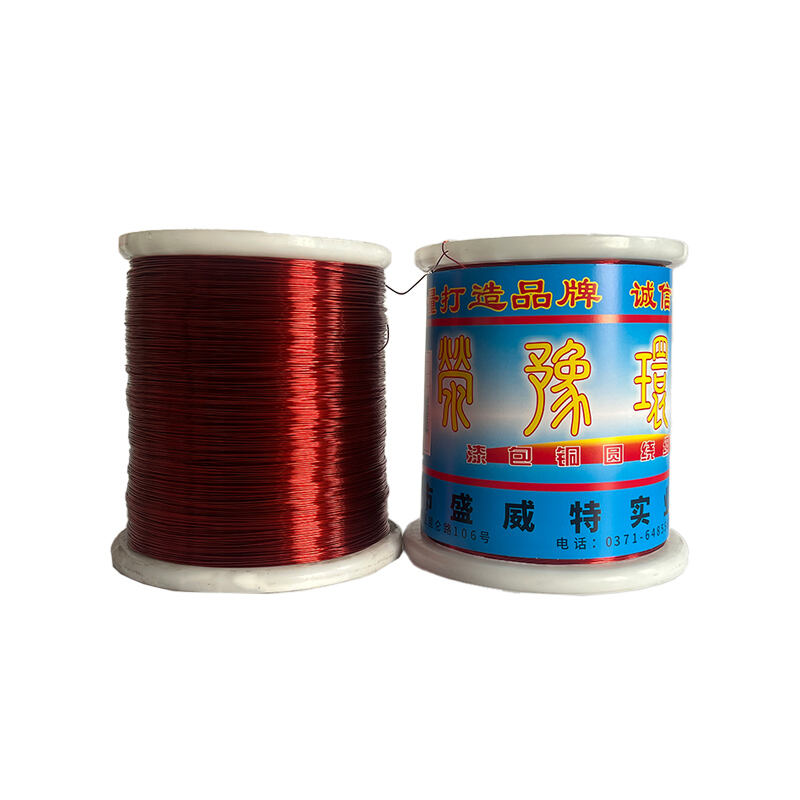

Copper at the core All electric motors start out as a copper coil. This coil consists of thousands of turns of copper wire that generate a magnetic field when electricity passes through it. This field comes into contact with other magnets of the motor resulting rotation, and the same corresponds to output that provides motion of the device.

One of the primary reasons why copper is the material of choice in coil production for electric motors, is due to it's high conductive properties. Copper is a good electrical conductor and can conduct energy, allowing you to move your hand across the surface quickly. Due to its high conductive nature, copper wire winding electric motors have the flexibility of encasing high speeds and minimum of energy loss, and making it suitable for devices that demand consistent and dependable jobs.

Not only are copper coils conductive, but they also have low resistance. This, in turn, enables them to conduct a great deal of current without the conductor overheating or losing energy. This is one reason copper coil electric motors are very efficient and powerful, and able to supply the power necessary to run anything from a diehard to an industrial tool.

When selecting materials for your electric motor, copper coils have several benefits. Copper Despite being a conductive and low resistance metal, copper coils are sturdy and resistant to rusting. That means that they can take the daily punishment and head problems that may come along with them, meaning longer-lasting, more reliable motors.

The copper winding is also very important in a motor which makes great improvements of the motor. The layout of the coil (number of loops, wire thickness) can influence things like speed, torque, and efficiency. As they excel at implementing copper as a motor wind material, producers can tailor motors to the specific performance requirements and deliver the kind of power necessary for various applications.

Copyright © Zhengzhou Shengweite Industrial Co.,Ltd. All Rights Reserved - Privacy Policy - Blog