A maioria de nós nem sequer pensa no enrolamento de fios de cobre, que é uma parte de muitas máquinas ou itens que usamos diariamente. É utilizado em motores, transformadores e geradores. Enrolar corretamente o fio de cobre é essencial; fazê-lo corretamente significa que a máquina funcionará melhor e durará mais. Na Shengweite, sabemos como produzir fios de cobre de boa qualidade e enrolá-los da maneira correta. Isso ajuda a manter os produtos dos nossos clientes funcionando excelentemente e economizando dinheiro. O enrolamento correto é essencial, seja para pequenos dispositivos ou máquinas industriais gigantescas. Para obter mais informações sobre os tipos de fios que utilizamos, consulte a nossa Fio plano opções.

Há algumas coisas que você vai querer considerar ao procurar um serviço para auxiliar com o enrolamento de fios de cobre. Uma delas é a experiência da empresa. Como a Shengweite, que atua nesse setor há muitos anos, até que profundidade e espessura eles realizam melhor. Eles sabem qual tipo de fio é ideal para diferentes usos e podem ajudar a controlar a quantidade necessária. A próxima coisa que você deve verificar é o tipo de equipamento que utilizam. "Isso faz uma grande diferença na qualidade do enrolamento obtido, especialmente com equipamentos modernos. Uma empresa com máquinas sofisticadas pode garantir que o fio seja enrolado firmemente e uniformemente, o que melhora o desempenho. Além disso, nossa Linha à prova d'água é um exemplo das soluções avançadas que oferecemos.

O custo também é um fator importante. Você está buscando qualidade e valor em um serviço que oferece bom custo-benefício, mas com alguma redução na qualidade. Há momentos em que a opção mais barata pode não ser a melhor no final. É sensato considerar como o efeito do enrolamento afeta o desempenho do seu produto como um todo. Se apresentar mau funcionamento precoce, você acabará gastando mais com reparos. Embora um serviço confiável como o da Shengweite possa custar mais inicialmente, a longo prazo ele pode ser o seu melhor custo-benefício. Por último, verifique as avaliações dos clientes. É útil ouvir de pessoas que já utilizaram o serviço: isso lhe dará uma boa ideia do que esperar.

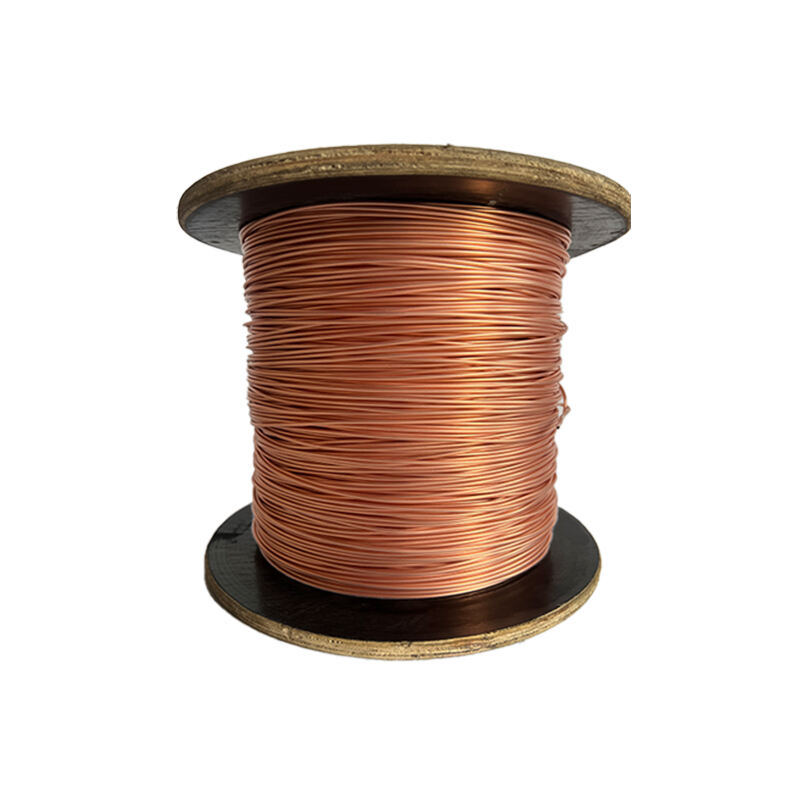

O enrolamento de fios de cobre é extremamente vital em aplicações elétricas como esta. Este é o processo de enrolar fios de cobre até que formem bobinas. Essas bobinas são utilizadas em uma variedade de dispositivos, como motores, transformadores e geradores. O fio de cobre é preferido por um motivo, e não apenas porque você pode facilmente encontrar fio de cobre em sua casa – o que naturalmente você tem. O cobre é um excelente condutor de eletricidade. Isso facilita a passagem da eletricidade sem que ela se deteriore. Se você enrolar um pedaço de fio de cobre de forma compacta, a maneira como o fio é enrolado determina seu campo magnético. Essa força magnética é crucial para o correto funcionamento de muitos dispositivos.

Por exemplo, o enrolamento de fio em fios de motor de cobre permite a conversão de energia elétrica em trabalho mecânico. Uma corrente elétrica passa através das suas bobinas de fio, criando um campo magnético que faz o motor girar. Os motores não poderiam funcionar de forma eficiente sem o enrolamento de fio de cobre. Transformadores também utilizam enrolamentos de fio de cobre para alterar a voltagem da corrente. À medida que a eletricidade flui através das bobinas, induz voltagens maiores e menores — uma etapa crucial para fornecer energia às residências e empresas com segurança. Na shengweite, focamo-nos na qualidade das nossas estratégias de enrolamento de fio de cobre para garantir que os nossos produtos sejam os melhores.

Na Shengweite, percebemos que o enrolamento de fio de cobre é uma parte essencial da eficiência. Prestamos muita atenção à forma como enrolamos nossos fios de cobre porque queremos que nossos dispositivos eletromagnéticos sejam tão fortes e produtivos quanto possível. Existem também uma variedade de outros fatores que podem alterar a eficiência, como a qualidade do cobre utilizado e o modo como o enrolamento é projetado. Podemos fazer a nossa parte, considerando a qualidade no projeto e buscando oportunidades para ajudar nossos clientes a aproveitarem ao máximo seus produtos eletromagnéticos. O enrolamento de cobre é indispensável para o desempenho dos instrumentos eletromagnéticos. Métodos corretos de enrolamento podem ajudar a melhorar o desempenho, reduzir o consumo de energia e garantir um funcionamento mais confiável.

O enrolamento com fio de cobre é excelente, mas existem alguns problemas que as pessoas podem enfrentar. Um dos principais problemas é que o fio pode arrebentar ao se aproximar do enrolamento durante o funcionamento. Esse dano pode causar conexões soltas e o mau funcionamento do dispositivo. E um terceiro problema aqui poderia ser o aquecimento do fio. Se passar muita eletricidade pelo fio, ele pode esquentar e até derreter o revestimento de isolamento. Isso pode levar a curtos-circuitos e até incêndios, se não for tratado adequadamente.

Direitos Autorais © Zhengzhou Shengweite Industrial Co.,Ltd. Todos os Direitos Reservados - Política de Privacidade- Não.Blog