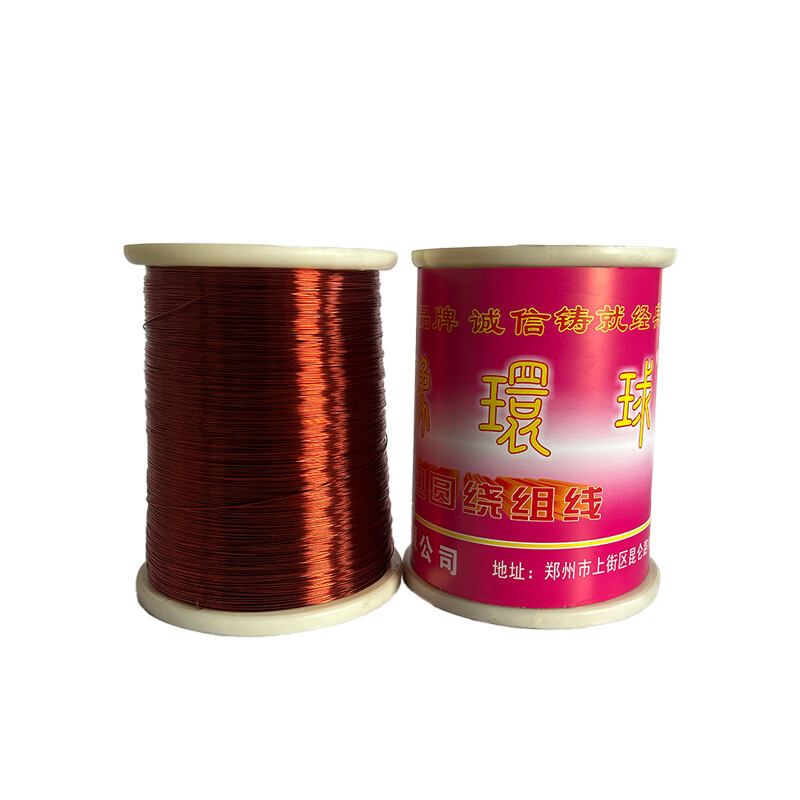

Კოჭის შეხვევის სამუშაო გამტარი სპეციალური ნაღმის გამტარია, რომელიც გამოიყენება მანქანებში. იმიტომ, რომ სპილენძი ელექტროენერგიის მიმართ შესანიშნავი გამტარია. როდესაც ეს გამტარი იკოჭება ანუ იხვევა წრეებად ან კოჭებად, ის ელექტრომაგნიტური ველის გენერირებაში ეხმარება, რაც აუცილებელია ძრავებისთვის, ტრანსფორმატორებისთვის და სხვა მოწყობილობებისთვის. გამტარის შეხვევის მეთოდი განსაზღვრავს მანქანის მუშაობის ეფექტურობას. თუ გამტარები ძალიან ხვეულად იქნება შეხვეული, ყველაფერი შეიძლება შეწყდეს. თუ ძალიან მკვრივად – გამტარი შეიძლება დაზიანდეს. ამიტომ კოჭის შეხვევის სამუშაო გამტარი უნდა იყოს ზუსტად და ხარისხიანი მასალით შესრულებული. ეს არ არის უბრალოდ ნებისმიერი გამტარი; ის უნდა იყოს მაგარი, მოქნილი და გრძელმად მუშაობადი. Shengweite-ში ჩვენ ვიღებთ ნაყოფიერებას იმით, რომ ვაწარმობთ კოჭის შეხვევის სამუშაო გამტარს, რომელიც აკმაყოფილებს ამ მოთხოვნებს და უზრუნველყოფს მანქანების უსაფრთხო და უწყვეტ მუშაობას. ჩვენი პროდუქტების ასортიმენტი ასევე შეიცავს Ჩამონტაჟებული მავთულის საწები , რომელსაც მსგავსი გამოყენება აქვს ელექტრომოწყობილობებში.

Როდესაც ხდება წრფის დიდი რაოდენობის შეძენა, მნიშვნელოვანია ხარისხი. დიდი მომხმარებლები, მაგალითად ქარხნები ან ბიზნესები, რომლებიც აწარმოებენ ელექტროძრავებს ან ტრანსფორმატორებს, სურთ ისეთი წრფის შეძენა, რომელიც არ გაწყდება და არ იწვევს პრობლემებს. Shengweite-ში ჩვენ ღრმად გავიგეთ ეს. ჩვენი სპილენძი სუფთა და სუფთაა — ის გადაჰქონს ელექტროენერგიას ენერგიის დანაკარგის გარეშე. ის ასევე დამუშავებულია სპეციალური მასალებით, ამიტომ თქვენი წრფე არ დაირუსება და არ ი wear out, მაშინაც კი, თუ გრძელი დროის განმავლობაში იყენებთ. წარმოიდგინეთ იმის ნაცვლად, რომ წრფე სწრაფად გაწყდეს და შესაბამისად შეაჩეროს მანქანები, რაც შეუქმნის პრობლემებს მომხმარებლებს. ჩვენ უზრუნველყოფთ, რომ ასეთი რამ არ მოხდეს. წრფის სისქე და ის, რამდენად გლუვია, ასევე შეიძლება გავლენა მოახდინოს იმაზე, რამდენად კარგად ემთხვევა ის მავთულის შემოხვევის მანქანებს. ჩვენ ყოველი პარტიის შემოწმება ძალიან ფრთხილად ვახდენთ, რათა თავიდან ავიცილოთ ნაკლებები. ზოგჯერ მავთულს შეიძლება ჰქონდეს პატარა ხვრეტები ან სუსტი ადგილები. ჩვენ ამას არ ვაკეთებთ, რადგან ეს შეიძლება გამოწვეული იყოს მოკლე ჩართვით ან გადახურვით. იმ მყიდველებმა, რომლებიც საბოლოოდ შეიძენენ წრფეს Shengweite-დან, იღებენ პროდუქს, რომელიც ზრუნვითაა დამზადებული, შემოწმდა შესაბამისი მანქანებით და დაფასებულია ისე, რომ ის შესრულდეს შესრულებული. ჩვენ გამოვლინეთ, რომ ბევრი მყიდველი ბრუნდება ჩვენთან, რადგან ისინი აფასებენ იმ ხარისხს და სერვისს, რომელსაც ჩვენ ვთავაზობთ. ჩვენ ვფიქრობთ, რომ ეს არ არის მხოლოდ წრფის გაყიდვა, არამედ ხალხის დახმარება უკეთესი მანქანების შექმნაში, რომლებიც გრძელი ხანი გრძელდება და უფრო ეფექტურად მუშაობს. კარგის შექმნის გრძნობა გვაძლევს წინ წასვლის შთაგონებას.

Მაგრამ კოჭის ტევადობის სპილენძის გასათვლელად კარგი მომწოდებლის არჩევა არ არის მარტივი. იმდენი მრავალი მომწოდებელი ამტკიცებს, რომ მათ აქვთ კარგი გასათვლელი, მაგრამ ზოგჯერ რეალობა სხვა რამეა. Shengweite-ში ჩვენ ვცდილობთ ვიყოთ სანდო მომწოდებელი. კარგი მომწოდებლის პოვნაში დამხმარე ფაქტორი ასევე ის არის, როდესაც კომპანიებს აქვთ ნათელი ინფორმაცია თავისი პროდუქტების შესახებ. ჩვენ ვთავაზობთ დეტალურ სპეციფიკაციებს ჩვენს გასათვლელზე — რამდენად მსხვილია, რა სახის საფარი აქვს, რამდენად მაგარია. კიდევ ერთი მნიშვნელოვანი ნაწილი არის მომხმარებელთა მომსახურება. ამგვარად, ჩვენ ვპასუხობთ ყიდვის შესახებ დასმულ კითხვებს და ვეხმარებით იმ გასათვლელის არჩევაში, რომელიც საუკეთესოდ შეესაბამება მათ საჭიროებებს. არა ყველა მომწოდებელი აკეთებს ამას კარგად, რაც მომხმარებლებს დაბნეულობაში ან უდავოდ ტოვებს. ჩვენ ვიმედოვნებთ „ურთიერთობაში“ გაყიდვამდე. ასევე მნიშვნელოვანია მიტანა. წარმოიდგინეთ იმ გაღიზიანება, როდესაც გელოდებით გასათვლელს, რომელიც არასოდეს მოდის. დროული მიტანა Shengweite ტრადიციული მწარმოებელი დროულად ატვირთავს და ყიდვები მოწონს პროდუქტი. ჩვენ ასევე უზრუნველყოფთ, რომ გასათვლელი სრულყოფილად იყოს დაფასტებული, რომ მისი გზა არ დაზიანდეს. ჩვენი ყიდვები შეიძლება მოვიდნენ ჩვენს საწარმოში და ნახონ, თუ როგორ ვქმნით გასათვლელს. ეს არის ის სახის ღიაობა, რომელიც იწვევს ნდობას. და, ჩვენ მუდმივად ვეძებთ გზებს, რომ უკეთესად გავაკეთოთ ჩვენი წარმოება უფრო მოწინავე ხელსაწყოებითა და ტექნიკებით, რათა ჩვენი გასათვლელი მაგარად გამოვიდეს ველზე ან თქვენს მაგიდაზე. როდესაც ყიდულობთ კოჭის ტევადობის სპილენძის გასათვლელს დიდი რაოდენობით, კომპანია როგორიცაა Shengweite შეიძლება დაგეხმაროთ დროის და გაღიზიანების დაზოგვაში. ჩვენ მეტი ვართ ვიდრე უბრალოდ გასათვლელის კომპანია, ჩვენ ვიმედოვნებთ რთული პრობლემების გადაჭრაში და ბიზნესის ზრდის შესახებ. ჩვენ ასევე ვაწარმოებთ Გარსით დახვეული სპილენძის/ალუმინის ბრტყელი დროშა სპეციალიზებული სამრეწველო საჭიროებების დასაკმაყოფილებლად.

Კოჭის მოტორის გა winding სამუშაო საჭიროა მრავალი ელექტრონული პროდუქის წარმოებისთვის, როგორიცაა ძრავები, ტრანსფორმატორები და დინამიკები. თუმცა, კოჭის მოტორის გა winding სამუშაო ყოველთვის არ არის ისე მარტივი, როგორც უნდა იყოს, და ასეთი გართულებები ხშირად იწვევს ზოგიერთ გავრცელებულ პრობლემას. ერთ-ერთი დიდი პრობლემა არის გამტარის გაწყვეტა. თვითონ გამტარი თხელი და ნა delicate ია, რაც ნიშნავს, რომ ის შეიძლება გაიწყვიტოს, თუ თქვენ ძალიან დაჭიმავთ ან ძალიან მკვეთრად დაამოგვარებთ. ეს შეაჩერებს მოტორის გა winding სამუშაოს და გამოწვეული იქნება მასალის დანახარჯი. ამის თავიდან ასაცილებლად, მნიშვნელოვანია გამტარის მიმართ ფრთხილად მოპყრობა და იმ ხელსაწყოების გამოყენება, რომლებიც არ გა stretch ს და არ გაწყვეტს გამტარს.

Გამათბობლის იზოლაციის დაზიანება კიდევ ერთი პრობლემაა. კოპრისგან დამზადებული გამტარი, რომელიც ხასიათდება სპირალური ფორმით, ჩვეულებრივ დაფარულია საკმაოდ თხელი იზოლაციური ფენით, რათა თავიდან იქნეს აცილებული ელექტროენერგიის გაჟონვა ან შემოკლება. სპირალის დროს იზოლაციის ნებისმიერი მცირე დაზიანება შეიძლება გამოიწვიოს კოჭის გაუმართაობა. იზოლაციის დაზიანების თავიდან ასაცილებლად, გამტარი უნდა გაწმინდეთ და გააგლუვოთ გახვეულობის დროს. მოაპირეთ გამტარი მანქანებით ან ხელით ისე, რომ მაგალითად მაგარი ან მახვლის ზედაპირები არ დაზიანებულიყვნენ. ასევე, ხშირად შეამოწმეთ გამტარი მისი გახვეულობის დროს, რათა დროულად შეამჩნიოთ ასეთი პრობლემები. დამატებითი საიმედოობისთვის, განიხილეთ გამტარის გამოყენება იმ Წყალგამძლე ხაზი პროდუქტის სერიიდან, რომელიც გაძლევთ გაუმჯობესებულ დაცვას.

Სპილენძის გამტარი ელექტრონიკაში კოჭების შესახვევად უფრო მოსახერხებელია, და ეს არ მხოლოდ იმიტომაა, რომ ის იაფია! სპილენძი ძალიან კარგად გაატარებს ელექტროენერგიას. ეს ნიშნავს, რომ მას აქვს ძალიან დაბალი წინაღობა და საშუალებას აძლევს ელექტროენერგიას იოლად გადაადგილდეს მის გასწვრივ — ეს კი მუშა კოჭების შესაქმნელად აუცილებელი თვისებაა. როდესაც ელექტრონები ასე მოძრაობენ სპილენძის გამტარის კოჭის გასწვრივ, ელექტრონული მოწყობილობა უფრო ეფექტურად მუშაობს და ნაკლებ ენერგიას იხარჯავს.

Მისი მუშავებადობა კიდევ ერთი მიზეზია, რის გამოც სპილენძი უპირატესობას იქნება. სპილენძის გამტარი მაგრამ მკვრივია, რაც საშუალებას აძლევს მას რამდენჯერმე შეიხვიოს კოჭებად გატეხვის გარეშე. ეს საშუალებას აძლევს მწარმოებლებს შექმნან კოჭები, რომლებიც იდეალურად შეესაბამებიან მოწყობილობებს — მაშინაც კი, თუ მოწყობილობები პატარა და რთული კონსტრუქციისაა. გარდა ამისა, სპილენძი მოქნილიც არის, ამიტომ ის შეუძლია გაუძლოს გადახრას და შეხვევას შეხვევის პროცესში და მაინც შეინარჩუნოს მისი მდგრადობა.

Copyright © Zhengzhou Shengweite Industrial Co.,Ltd. All Rights Reserved - Პირადულობის პოლიტიკა-Ბლოგი