Kawat tembaga digunakan dalam semua jenis lilitan kumparan, kebutuhan umum untuk berbagai aplikasi elektronik. Penggulungan kawat mengelilingi suatu inti untuk membentuk kumparan inilah yang kita sebut sebagai lilitan kumparan, dan sering digunakan pada motor, trafo, dan induktor. Tembaga secara luas digunakan untuk pekerjaan ini karena memiliki karakteristik listrik yang sangat baik. Di Shengweite, kami memahami pentingnya kawat tembaga berkualitas tinggi dalam memastikan fungsi perangkat yang efektif serta efisiensi energi. Artikel ini akan menjelaskan mengapa kawat tembaga merupakan pilihan terbaik untuk lilitan kumparan dan cara memilih kawat yang tepat sesuai kebutuhan Anda.

Mengapa kabel tembaga merupakan yang terbaik untuk lilitan kumparan? Pertama-tama, kabel tembaga sangat konduktif. Artinya, kabel ini merupakan penghantar listrik yang baik, yang sangat penting bagi perangkat apa pun yang harus bekerja secara efisien. Jika kabel merupakan penghantar listrik yang buruk, hal ini dapat menyebabkan perangkat tersebut menjadi terlalu panas atau bahkan tidak berfungsi sama sekali. Selain itu, tembaga merupakan material yang sangat kuat. Kabel ini mampu menahan banyak tekanan dan kerusakan, sehingga kumparan cenderung tahan lama. Hal ini sangat penting pada mesin yang beroperasi secara terus-menerus, seperti motor yang digunakan di pabrik. Selain itu, menggunakan produk berkualitas seperti Kabel tahan air dapat semakin meningkatkan ketahanan dan kinerja kabel Anda.

Akhirnya, perlu dicatat bahwa kabel tembaga sangat mudah ditemukan dalam berbagai ukuran dan konfigurasi tepat di planet ini. Ketersediaan yang beragam ini juga berarti bahwa tidak peduli proyek apa yang sedang Anda kerjakan, kemungkinan besar ada kabel tembaga yang sangat cocok untuk proyek Anda. Jadi, dapat disimpulkan bahwa kabel tembaga adalah yang terbaik untuk lilitan kumparan karena faktor-faktor berikut: kualitas konduktivitas yang baik, ketahanan, kelenturan, korosi yang sedikit atau tidak ada sama sekali, serta ketersediaan yang luas. Selain itu, pertimbangkan untuk menggunakan Kawat datar tembaga email Q (ZYXY) (EIAIWB200) untuk aplikasi tertentu yang memerlukan isolasi dan kinerja yang ditingkatkan.

Temukan Kawat yang Tepat Sesuai Kebutuhan Lilitan Anda Saat Anda ingin mengembangkan prototipe atau memulai suatu proyek, Anda selalu membutuhkan waktu dan kesabaran untuk menemukan jenis kawat yang tepat untuk lilitan kumparan. Pertimbangkan terlebih dahulu ukuran kumparan yang Anda butuhkan. Kawat tembaga tersedia dalam berbagai ketebalan, atau ukuran gauge. Kawat yang lebih tebal dapat menghantarkan arus lebih besar tetapi lebih kaku. Jika kumparan Anda terlalu kecil, Anda mungkin perlu mempertimbangkan kawat yang lebih tipis. Sebaliknya, jika ukurannya besar, mungkin kawat yang lebih tebal akan lebih disukai.

Terakhir, pertimbangkan biayanya. Dan meskipun mungkin menggoda untuk memilih rencana termurah, dalam hal kesehatan Anda, kualitas sangat penting. Terkadang layak mengeluarkan sedikit lebih banyak untuk kawat yang tahan lebih lama dan memberikan kinerja lebih baik. Pada akhirnya, kawat lilitan tembaga yang tepat untuk aplikasi Anda didasarkan pada ukuran, isolasi, arus, kualitas, dan biaya. Berikut adalah pertimbangan-pertimbangan yang perlu Anda perhatikan dan dengan demikian, Anda akan mendapatkan nilai yang sepadan dengan uang Anda.

I. Masalah umum penggunaan kabel tembaga untuk lilitan kumparan: 1. Untuk memulai, kabel dapat mudah putus jika tidak ditangani dengan hati-hati. Tembaga memang kuat, tetapi menjadi rapuh jika ditekuk terlalu sering. Hal ini dapat terjadi saat melilitkan kabel menjadi kumparan. Jika kabel dililit terlalu kencang, atau teknik yang digunakan salah, kabel bisa patah. Selain itu, kabel tembaga dapat memanas ketika arus listrik mengalir melaluinya. Fenomena ini disebut hambatan. Jika lilitan kumparan tidak rapi atau jika diameter kabel terlalu kecil, panas akan dihasilkan. Hal ini dapat merusak kumparan atau menyebabkan kebakaran jika suhu terlalu tinggi. Memastikan pemilihan ketebalan kabel yang sesuai akan membantu menghindari masalah-masalah tersebut. Selain itu, kabel tembaga dapat teroksidasi, sehingga berubah warna atau tertutup lapisan karat saat terpapar udara. Oksida ini dapat menyebabkan koneksi longgar dalam rangkaian listrik. Untuk mencegah hal ini, kabel harus disimpan di tempat kering dan segera digunakan setelah kemasan dibuka. Terakhir, jumlah kabel tembaga yang harus dililitkan cukup banyak! Jika tidak hati-hati, atau dilakukan terburu-buru, kabel bisa melilit secara tidak terduga. Hal ini dapat menyebabkan kumparan tidak berfungsi seefektif seharusnya. Untuk menghindari masalah-masalah ini, penting untuk mempelajari teknik yang tepat dan meluangkan waktu agar pekerjaan dilakukan dengan benar. Kabel berkualitas baik yang dipasok oleh produsen terpercaya seperti Shengweite dapat membantu meminimalkan masalah ini, sehingga menghasilkan lilitan kumparan yang lebih baik.

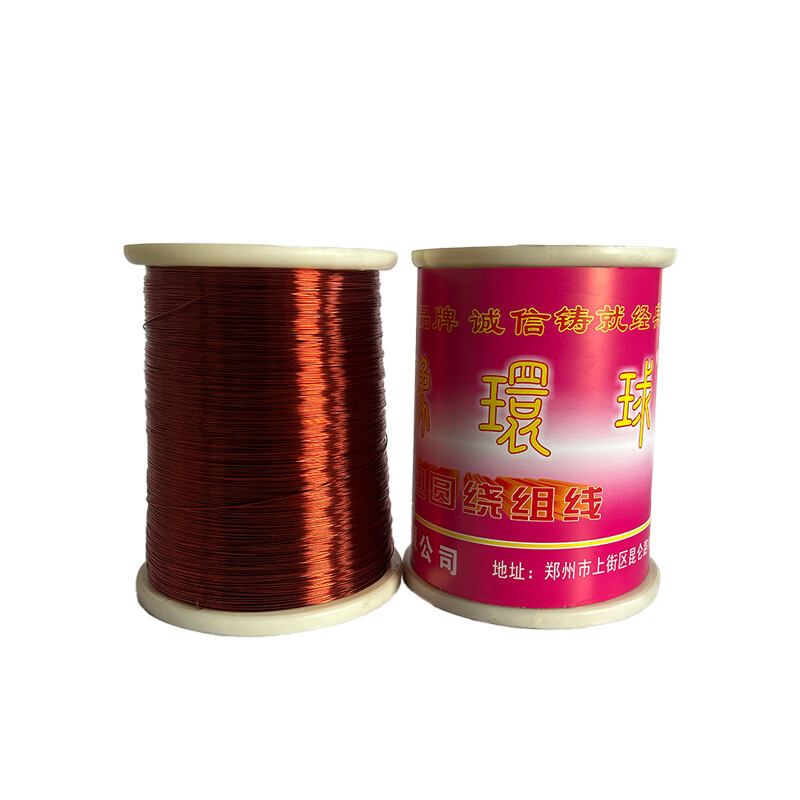

Kawat tembaga beremail adalah salah satu pilihan paling populer untuk lilitan archy, dan memiliki beragam manfaat. Salah satu manfaat utama adalah lapisan pelindung yang unik. Lapisan inilah yang melindungi kawat agar tidak putus. Ketika kawat dilapisi enamel, hal ini membantu mengurangi kerusakan atau putus saat proses lilitan. Artinya, orang dapat membuat kumparan yang lebih kuat dan lebih baik. Kawat Tembaga Beremail juga memiliki karakteristik listrik yang sangat baik. Hal ini membuat kumparan berfungsi lebih efektif dengan memungkinkan aliran listrik mengalir dengan mudah. Ini sangat penting untuk perangkat seperti motor dan trafo, yang membutuhkan kinerja listrik yang baik. Kawat beremail dapat membuat perangkat-perangkat ini bekerja lebih baik dan lebih efisien. Manfaat lainnya adalah kawat beremail jauh lebih tipis dibandingkan kawat tembaga polos. Ini sangat menguntungkan karena artinya lebih banyak kawat dapat dimasukkan ke dalam ruang yang lebih sempit. Saat Anda melilit kumparan, semakin banyak kawat dalam ruang kecil dapat menghasilkan medan magnet yang lebih kuat. Ini sangat penting untuk sebagian besar peralatan listrik. Selain itu, kawat tembaga beremail jauh lebih mudah digunakan. Lapisan tersebut membuatnya jauh kurang lengket, sehingga sangat kecil kemungkinannya kusut saat ditarik dari gulungan. Ini sangat membantu menghemat waktu dan tenaga saat mengerjakan proyek. Selanjutnya, kawat beremail juga lebih tahan terhadap oksidasi. Jadi, kawat ini bisa sangat tahan lama dan bertahan dalam waktu lama. Bagi siapa pun yang melakukan lilitan kumparan, kawat tembaga beremail dari merek terpercaya seperti Shengweite adalah pilihan terbaik. Produk ini mendukung proses yang lebih mudah, memberikan kontribusi pada produk yang lebih baik, serta menjamin kumparan akan berfungsi sebagaimana mestinya—dalam jangka waktu panjang.

Hak Cipta © Zhengzhou Shengweite Industrial Co.,Ltd. Seluruh Hak Dilindungi Undang-undang - Kebijakan Privasi- Aku tidak tahu.BLOG